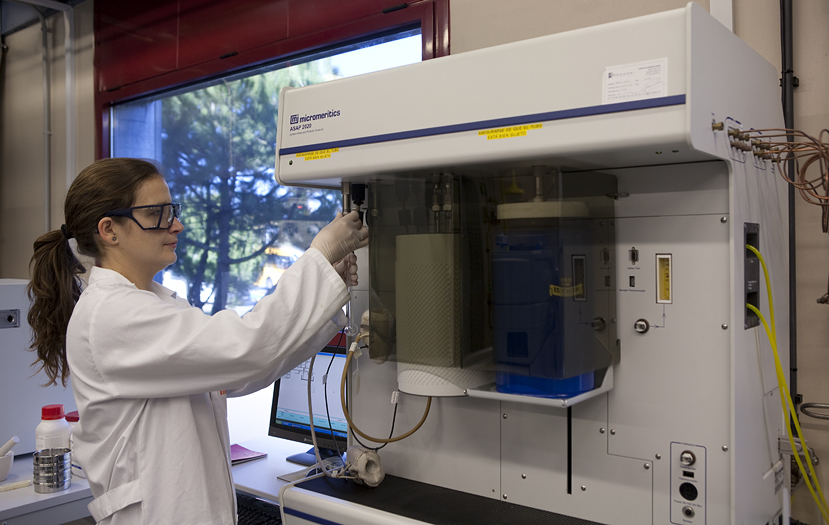

The Gas Reactivity laboratory is designed for the study of the reactivity and adsorption of a variety of gases into liquids or solids materials employing volumetric as well as gravimetric techniques and over a wide range of pressures and temperatures. This laboratory also includes equipment for the preparation of new materials for absorption of gases by sputtering in UHV and several potentiostats for electrochemical studies.

Assigned personnel

|

|

|

Joaquim Torres

Technical Lead

|

Related research lines

|

Materials for Energy |

CO2 utilization |

Available equipment

| Equipment Description | Features | Main Applications | |

| AMEL 7060 |

Voltage range: ±10 V |

Batteries, fuel cells and other energy-related studies Preparative electrolysis Generation of gases Electrochemical testing of materials |

|

| PARSTAT 2273 |

Maximum current: 2 A |

Liquid/solid electrochemical |

|

| UHV Sputtering system |

4 off-axis 2” magnetron sources: |

Growth of thin films and multilayers of metallic elements. |

|

| AccuPyc 1340 Pycnometer |

Temperature: Stable between 15C -35C Frequency: 50 to 60 Hz |

Determine density measurements for metal oxides, refractories, carbon black, activated charcoal, amorphous silica, metal powders, ceramics, graphites, cokes, catalysts, etc. |

|

| BET ASAP 2020 |

Two independent vacuum systems |

Medical implants and pharmaceuticals Ceramics Activated carbons Paints and coatings Electronics Nanotubes. |

|

| Swing Sorption Reactors |

Max pressure: 30 bar Temperature range: Adsorption mode: 25 to 750C Absorption mode: 25 to 150C Sorption feed flows: Desorption feed flows: Column: |

Pressure Swing Adsorption. |

|

| Small Microbalance | Max pressure: 30 bar Temperature range: 5C to 450C Weight: Range: 0 – 25 g Resolution: +/- 0.01 mg Repeatability: +/- 0.04 mg Gases Flows: Carbon Dioxide: 2 Nl/min Nitrogen: 2 Nl/min Steam: 10 Nl/min Gases can be easily changed to Methane, Hydrogen, Carbon monoxide, Helium and Argon. Volumes: Sample vessel 500 ml Knockout pot 300 ml |

Compact microbalance system for TG measures and sorption properties under a medium range of conditions. |

|

| IMS – HP HT Microbalance | Standard cell: Max pressure: 125 bar (H2); 85 bar (Others gases) Temperature range: 5C to 500C High temperature cell: Maximum pressure: 35 bar Maximum temperature: 850C Repeatability: +/- 2 μg Gases: Argon, Carbon Dioxide, Helium, Methane, Steam On line mass spectrometer |

Unique integrated microbalance system for TG measures and sorption properties under a broad range of conditions. |

|

| TGA Q5000 IR | Temperature controlled thermobalance Dynamic Range: 100 mg Weighing Accuracy: +/-0.1% Weighing Precision: +/-0.01%Sensitivity: < 0.1 μg Signal Resolution: 0.01 μg Temperature Range: Ambient to 1200 °C Isothermal Temp Accuracy: +/-1 °C Linear Heating Rate (°C/min): 0.1 to 500 Furnace Cooling (Forced air / N2): 1200 to 35 °C < 10 min Autosampler –25 sample Vacuum: 10-2torr Sample Pans • Platinum 50, 100 μL • Platinum-HT, 100 μL • Ceramic 100, 250 μL • Aluminum 80 μL • Aluminum Sealed Pan 20 μL. |

Thermogravimetric Analysis allows measuring the amount and rate of change in the weight of a material as a function of temperature or time in a controlled atmosphere. |

|

| GC6890N Gas chromatograph | Channels: 2 Split/splitless: per channel Detector: FID per channel Online gas sampling Online liquid sampling Chemstation |

Gas analysis Micropoluntant analysis Online analysis |

|

matgas.org

matgas.org