In the Supercritical Fluids laboratory research and development of new applications of supercritical fluids or fluids at high pressures and temperatures is carried out. This includes extraction and concentration of natural products, polymer impregnation, CO2 transportation and sequestration and synthesis of new materials and catalysts. The laboratory is equipped with several high pressure reactors with different configurations and sizes, from 10 ml to 16 l; it also includes a pilot plant.

Assigned personnel

|

|

|

|

Related research lines

|

Materials for Energy |

CO2 utilization |

Available equipment

| Equipment Description | Features | Main Applications | |

| 100 ml HP reactor |

Maximum pressure: 200 bar |

Homogenous catalysis |

|

| SCF 300 ml Plant |

Maximum pressure: 227 bar |

Synthesis of aerogels in different shapes |

|

| Supercritical Continuous Plant | Maximum pressure: 250 bar Maximum temperature: 150C Number of vessels: 3 Vessel volume: 10 ml Maximum CO2 flow: 5 l/min Temperature control: external electrical furnace |

Equipment designed to carry out experiments at laboratory scale using supercritical CO2, pure or mixed with cosolvents or additives. |

|

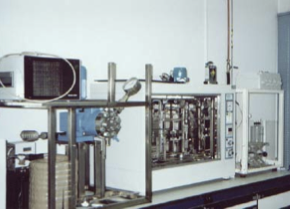

| Supercritical Pilot Plant |

Maximum pressure: 500 bar |

Pilot plant prepared to reach pressures and temperatures up to 500bar and 400oC. |

|

| SCF View Cell Thar | Maximum pressure: 410 bar Temperature range: ambient to 150C Volume range: 5 to 20 ml Sample homogenization by agitation CCD camera connected to computer for video capture. Pumping system: 1-50 g CO2/min Mixer |

Variable volume vessel with three sight glasses, designed to determinate the phase equilibrium of a mixture of two or more components at constant pressure, volume or mass. |

|

| SCF 100 ml mini reactor |

TMaximum pressure: 200 bar. |

Small high pressure –Medium temperatures reactor. |

|

| View Cell - Supercritical | Maximum pressure: 300 bar. Temperature range: -40 to 100C. Volume range: 20 to 50 ml. Sample homogenization by agitation at bottom and liquid phase recirculation. Sight glass length: 220 mm – the whole internal volume. Number of pumps: 3 Isco syringe pump (compressed gases), Jasco micropiston pump (atmospheric liquids), Micropump high pressure recirculating pump. |

Variable volume vessel with two transparent walls designed to determinate the phase equilibrium of a mixture of two or more components at constant pressure, volume or mass. |

|

matgas.org

matgas.org